-40%

M600 Mandrel Tubing Bender w/ 1.625x4.5 radius die set and mandrel for .083 wall

$ 2137.34

- Description

- Size Guide

Description

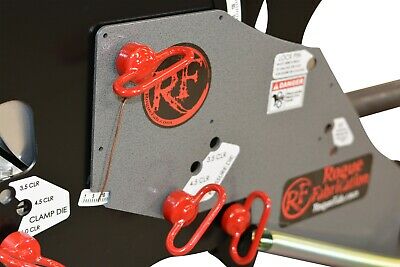

This is our M600 Tubing Bender with our Mandrel Attachment. With the wide range of options for our model 600 tubing bender, you can always add more dies, more mandrels, and other accessories like automatic stops for repeats bends and other specific tasks.In this product listing, you are buying our HD capacity model 600 Tubing bender. You are getting is

welded and painted

from us, exactly like the one in the picture. You area also getting the air/hydraulic cylinder shown, one die (1.625 diameter tube bending on a 4.5 inch radius), the mandrel attachment (welded and painted like the picture), and one mandrel (for 1.625 OD .083 wall tubing). It is the same as the machine in the photo. We have many dies and mandrel that fit this machine, if you are looking for another size, please contact us!

The M600 was designed specifically for use with mandrels from the very beginning. This machine features CNC Laser cut and formed A36 steel frame components for an accuracy and rigidity. The oversized 1″ ACME drive screw extracts the mandrel with absolute ease. This mandrel attachment includes our premium thru-mandrel lubrication injection system, affording you longer mandrel life and even higher bending performance.

Note – The pump shown in the photos was a protptype, we now have transparent-reservoir Made-in-USA pumps installed with CNC machined billet aluminum and cast components. They are top of the line and don’t leak past the piston with bending lube like standard pumps do!

This system is adjustable (up and down) to accommodate 2.5 CLR, 3.5 CLR, 4.5 CLR, and 6.0 CLR dies (this package includes one die, and CLR stands for Center Line Radius, the size of the bend). The mandrel position is adjustable front to back to precision tune your bend, just like on large 0K plus mandrel benders. Mandrel position can be saved with an acme locknut for effortless repeat positioning. This attachment is meant to be used with our high nickel bronze alloy mandrels, which are a high strength industrial mandrel featuring good surface lubricity (again, just like 0K+ industrial machines).

This allows you to bend thin walled titanium (in some applications), stainless exhaust components, header elbows, turbo manifold tubes, and more with ease. We keep accurate records of all of our testing and what position the mandrel is in so you can leverage our experience and expertise into your own success and profit.

The RogueFab Model 600 the most affordable mandrel bender in the world that can bend over 1 inch OD steel tubing. And it’s all made right here in the USA, from the mandrels to the frame components and machined parts to the ACME screw. Only limited hardware components and the air/hydraulic cylinder are imported. The max diameter is 2 inches (with a 2 inch die of course).

Additional arbors and additional die sets for the bender are available at our web page at.